Next: How to Choose the Right Cup Lid Making Machine for Your Business

The humble paper cup is a ubiquitous part of modern life, found everywhere from coffee shops to water coolers. If you're considering entering the paper cup manufacturing business or upgrading your production, understanding the paper cup making machine price is crucial. This guide breaks down costs, explores the manufacturing process, raw materials, applications, and answers common questions.

The cost of a paper cup making machine varies significantly based on factors like automation level, production capacity, and additional features. XinxinLi offers 3 kinds of paper cup making machine:

The JBZ-150B fully automatic high-speed paper cup machine has a rated speed of 120-150 cups per minute, supports paper cups from 4 ounces to 16 ounces, and is suitable for paper materials ranging from 190 to 350 g/m2. The whole process is automated, and the cup mouth is double-curled to ensure the exquisite shape of the paper cup, which is very suitable for mass production and high-end brand customization.

Cup Size: 4-16 OZ

Cup height: 60-135mm

Production speed: 120-150 cups per minute

Paper size: 190 to 350 g/m2

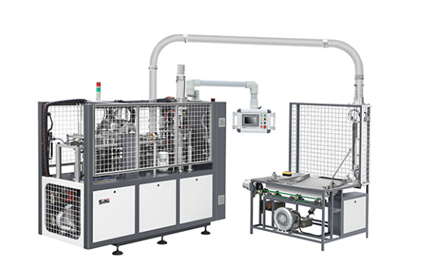

JBZ-122D Mid-Speed Disposable Cup Making Machine adopts the latest technology to make it energy-efficient, economical and durable. The shape is exquisite and the molds can be changed. SiNi will strive continuously to pursue the excellence in science and technology innovation. This paper cup forming machine adopts open cam design, automatic oil lubrication system and PLC control system to improve the machine function and performance.

Cup Size: 4-16 OZ

Cup height: 60-135mm

Bottom diameter: 40mm-70mm

Bottom depth: 5mm- 8mm

The JBZ-22D Automatic Mid-Speed Paper Cup Machine adopts an open cam design, automatic oil lubrication system and PLC control system to ensure that high-quality, consistent paper cups can be obtained. It is an ideal choice for companies seeking a balance between speed and precision. The JBZ-22D medium-speed paper cup forming machine has user-friendly controls and a sturdy structure to optimize the manufacturing process and reduce operating costs. It is well suited to meet a variety of production needs.

Cup Size: 4-22oz

Cup height: 60-180mm

Raw material: Single PE coating paper, Single and double PE coating paper

How much is a paper cup machine? Most of the price of Disposable Paper Cup Making Machine ranges from $8,000 to $ 30,000 per set. A set of paper cup molds costs about more than $1,300.

Modern paper cup machines transform rolls of specialized paper into finished cups through a continuous, automated process:

Unwinding: A large roll of PE or PLA-coated paperboard is loaded and fed into the machine.

Printing: If cups require branding or designs, this can be done beforehand on the paper roll or integrated inline on some advanced machines.

Die-Cutting: The paper is precisely cut into flat, cup-shaped blanks ("cup fans").

Cup Body Forming: The blank is wrapped around a mandrel (a cone-shaped form) and the side seam is sealed using heat and pressure, creating the tube.

Bottom Forming & Sealing: A pre-cut paper disk (the bottom) is fed into position. The bottom of the tube is heated and pressed onto the disk, creating a watertight seal.

Rim Curling: The top edge of the cup is curled outwards for comfort and rigidity.

Ejection & Stacking: The finished cup is ejected from the mandrel and automatically stacked for packaging.

Base Paperboard: Typically virgin or recycled wood pulp paper, chosen for strength and food safety compliance.

Coating: Essential for making the cup liquid-proof and heat-sealable.

Polyethylene (PE): The most common coating. Provides an effective moisture barrier. Suitable for cold and hot beverages (within limits).

Polylactic Acid (PLA): A plant-based (e.g., corn starch) biodegradable and compostable (under industrial conditions) coating. Used for "eco-friendly" cups. Requires specific composting facilities.

Inks: Food-safe inks used for printing designs and branding.

Hot Beverages: Coffee, tea, hot chocolate (using PE or PLA coated cups).

Cold Beverages: Soft drinks, juice, water, iced coffee/tea.

Food Service: Soups, ice cream cups, yogurt pots, portion cups for sauces/condiments.

Promotional Items: Custom printed cups for events, marketing campaigns, or branded giveaways.

Institutional Use: Water cups in offices, schools, hospitals, and public facilities.

Specialized Containers: Popcorn buckets, takeaway food containers.

Investing in a paper cup making machine offers scalability and profitability, with prices ranging from $8,000 to $30,000 depending on output and features. As sustainability drives innovation, machines supporting PLA coatings and AI automation are reshaping the industry. By understanding costs, production processes, and applications, businesses can make informed decisions to meet market demands efficiently.

Q1: Can one machine make only one size or different sizes?

A: Our machine can make different sizes. Different models have different size range. You can change the mold to change the size. Machine is supplied with one set of mold.

Q2: What’s the machine voltage?

A: Our standard machine voltage is 380V, 3-phase, 50HZ (workable for 50-60HZ). If you have other voltage requirement, you can buy a transformer.

Q3: What’s the required space for the paper cup machine?

A: For one cup machine, you will need around 12 square meters. But you will also need additional space for paper and ready cup storage. We recommend the warehouse space should be at least 60 square meters.

GET A QUOTE