Many paper bowl manufacturers often wonder: when the market demands different sizes or shapes of paper bowls, will switching production be time-consuming or complicated? This article breaks down key factors to answer whether such switching is truly troublesome.

The trouble of switching production does not depend on the size or shape itself, but on the design and functions of the equipment used. Below are three core factors that directly affect the switching process.

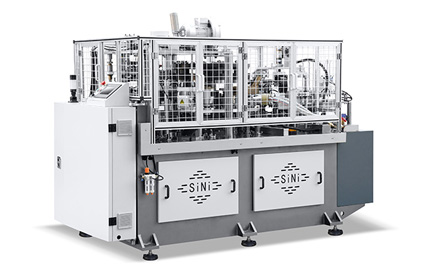

The core of switching paper bowl sizes and shapes lies in mold replacement. Modern Paper Bowl Machines are designed with mold compatibility in mind—most use standardized mold interfaces. This means you don’t need to disassemble large parts of the machine when replacing molds; you just lock the new mold into the designated position. For common sizes (such as 8oz to 12oz round bowls), the entire replacement process typically takes 30 minutes to an hour, which is far less cumbersome than traditional machines that require extensive adjustments.

Semi-automatic and fully automatic Paper Bowl Machines differ greatly in switching ease. Semi-automatic machines may require manual adjustment of components like feeding speed or heating temperature when switching, which adds steps and increases the risk of errors. In contrast, fully automatic models integrate smart control systems—they can automatically adjust key parameters (such as pressure, forming time, and material feeding rate) based on the selected size or shape. This reduces manual intervention, making the switch smooth and consistent.

To further simplify switching, many Paper Bowl Machines come with pre-set programs for popular paper bowl specifications (e.g., standard round 10oz soup bowls, square 16oz salad bowls). When you need to switch, you only need to select the corresponding program on the machine’s control panel. The machine will then apply the optimal settings automatically, eliminating the need to reconfigure parameters from scratch. This feature not only cuts down on switching time but also reduces the learning curve for operators.

In summary, switching production between different sizes and shapes of paper bowls is not inherently troublesome. It mainly depends on three factors: whether the Paper Bowl Machine has compatible, easy-to-replace molds; whether it has a high automation level; and whether it offers pre-set programs for common specifications. With the right equipment, the switching process can be efficient and hassle-free, helping you adapt to market changes quickly without sacrificing production efficiency.

If you want to learn more about Paper Bowl Machines that excel in flexible production switching—whether in terms of mold compatibility, automation, or pre-set functions—you can visit our product page to explore detailed specifications and features tailored to multi-specification production needs.

GET A QUOTE